Bubble Wrap Seat

Sustainable Furniture in a Minimal Approach

2020

How Could Bubble Wraps be Sustainable?

Bubble wrap sheets, which are made from #4 LDPF, a material that many municipal recycling programs don’t accept, could have disturb the sustainable vision for this project. However, the major factors influencing bubble wrap’s sustainability in its life cycle are acquiring petroleum and refining it to plastic. To counter the most environmentally damaging steps in a life cycle, I collected discarded bubble wraps and repurposed them into part of a seat, noticing how bubble wraps are often kept complete after used.

Playing with garbage before starting this project.

Obvious. Instinctive.

This project starts with a thinking of an obvious design, making the product obviously recyclable, one that all users would understand its recyclability immediately without even thinking.

To achieve this, we need to use material that people are already very familiar with and would recycle without a doubt, cardboard.

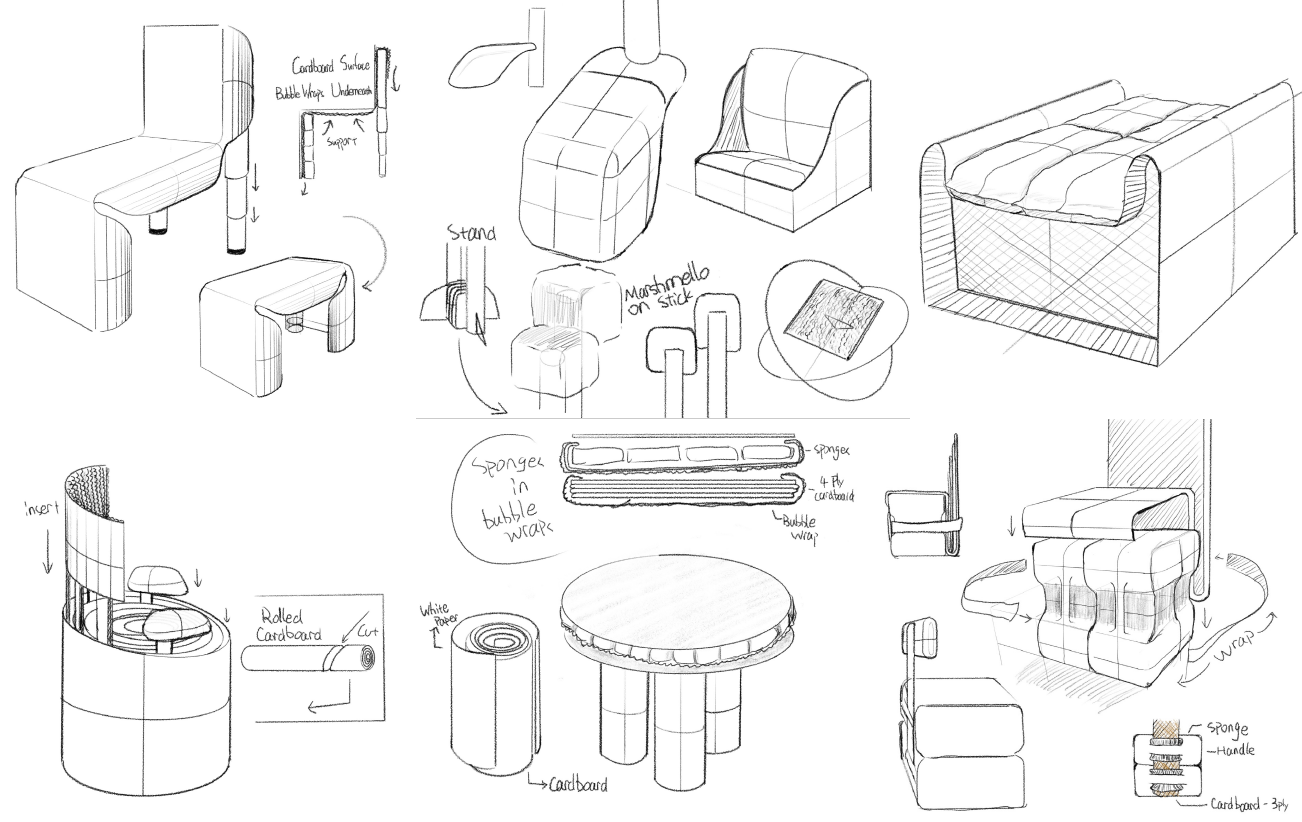

1st Stage Ideation

2nd Stage Ideation with Mini Models

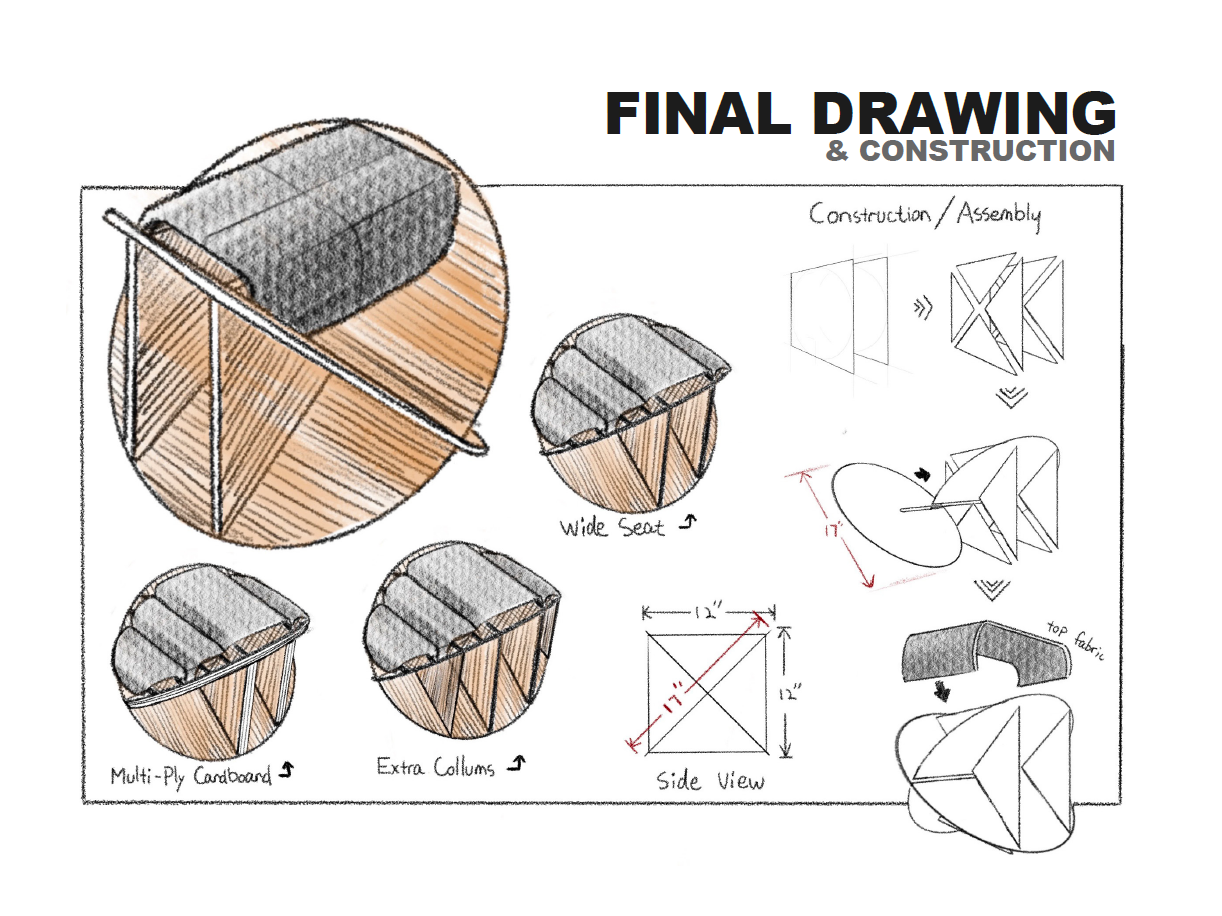

Geometric Composition

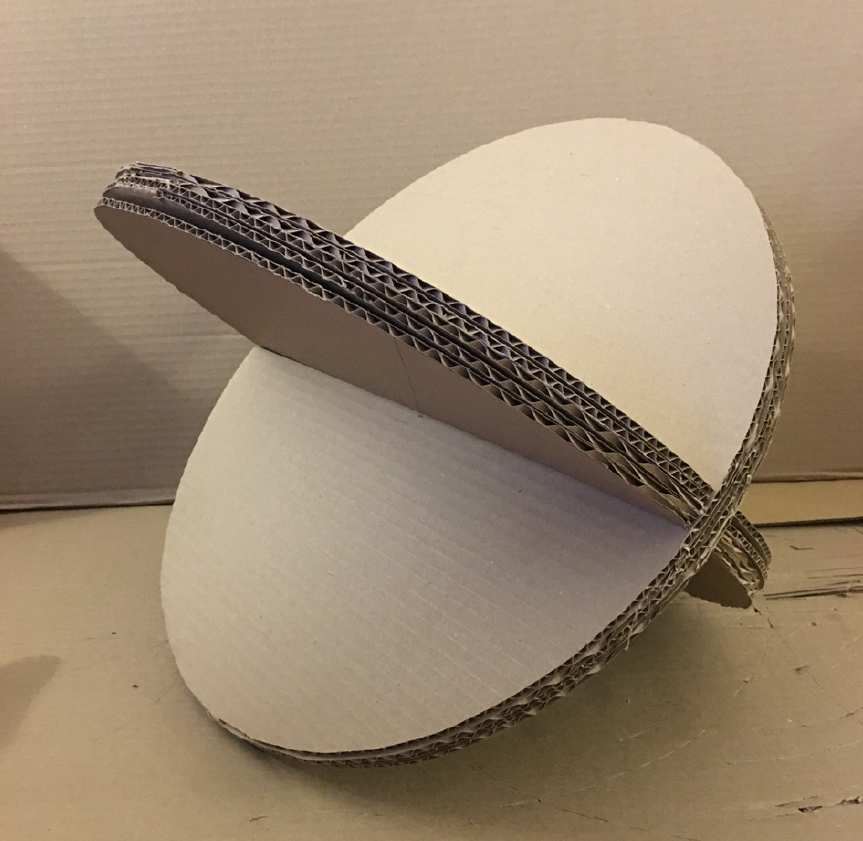

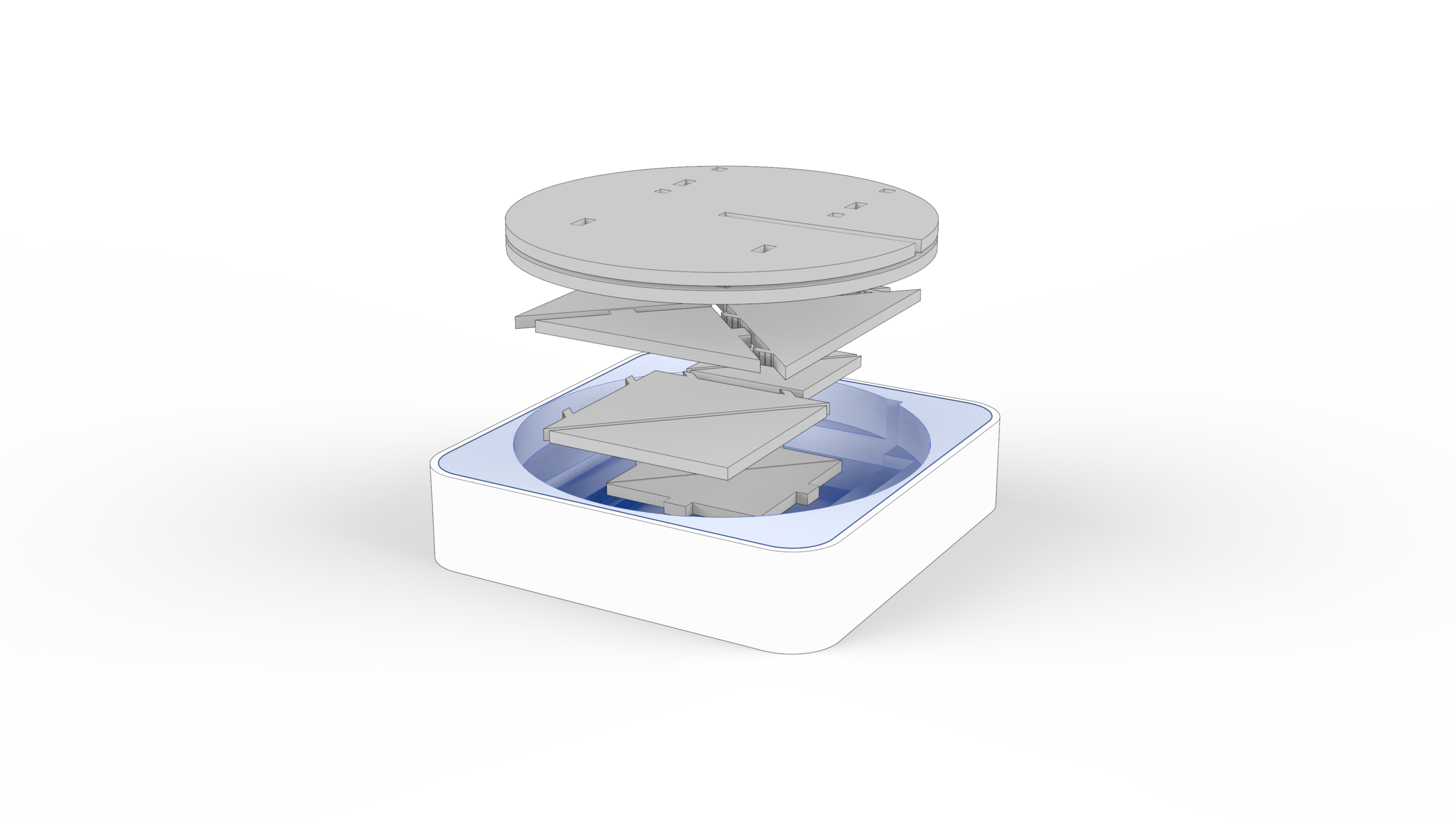

The specific solution chosen for further approach was a spherical one, constructed by multiple planes in simple geometry.

This way of assembly let user easily understand all of its contents and minimize both structural and visual complexity.

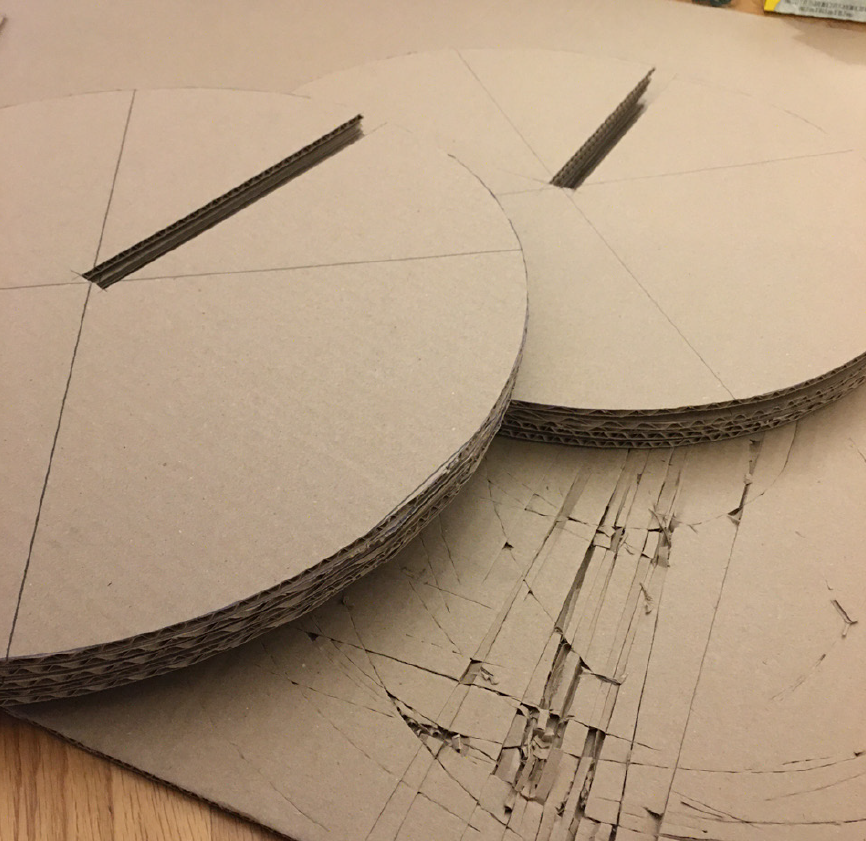

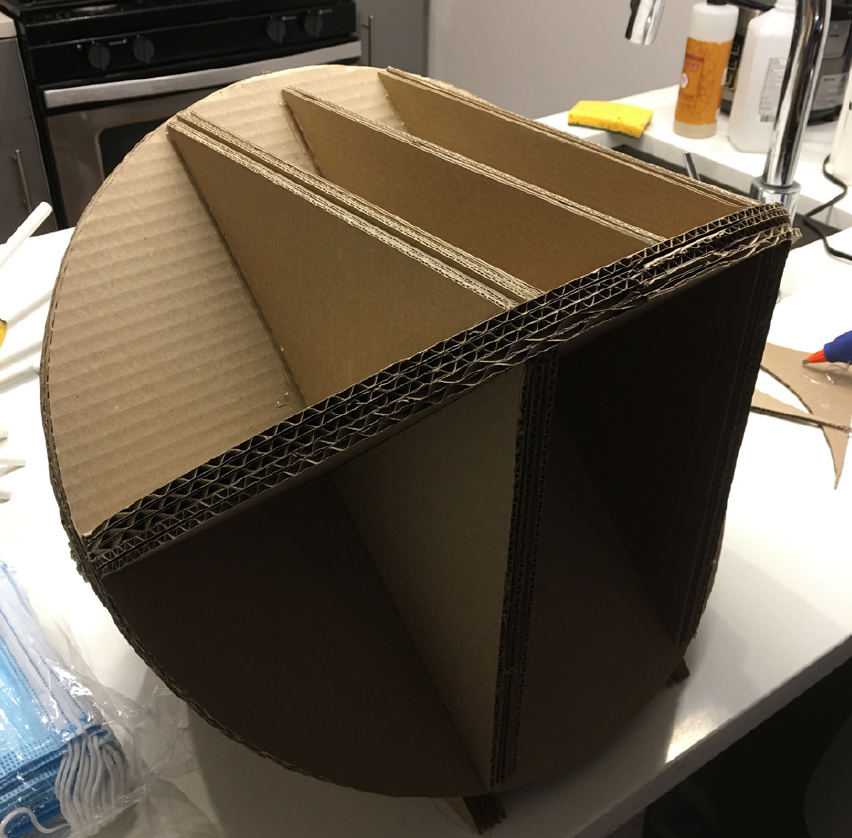

Crafting

I had no compass that could draw a 17” circle, so I found a piece of rectangular cardboard and poke two holes distanced by 17”, put two pencils in the holes to form a customized compass.

To fix the triangles in place, I used glue gun for this model. Yet in the digital model or future models, they will be assembled by techniques similar to wood joinery.

1:1 Physical Model

The bubble wraps could perfectly mimic the exterior and the function of paddings.

The height of the seat decides that it is meant to be only a small stool, and it fits people below 170cm comfortably and ergonomically.

The model is extremely light weight, and extremely durable. It is not broken after 2 years of regular use (but it’s broken now). If the model was built by denser cardboards, and was constructed by joints instead of glues, it could be even more durable.

Flat-Pack

Besides its lightweight feature, this seat could also be easily flat packed.

With thermoformed paper inner shell to hold the parts tight in place, the size of the packing could be as small as 18”x 18”x 5.5”.

Source of Materials

Due to the very regular geometry and flatness of the parts in the seat, the production for cardboard parts could be superiorly efficient.

The bubble wraps were collected from the package room in my apartment and from the supermarkets.